Prefab Steel Structure Poultry Breeder House

It is easy to manage and the market is on your doorstep. A well managed Poultry Breeder House is very profitable. In addition to designing and constructing poultry shed, we install all associated controlling, heating, cooling, feeding and watering systems – a complete turn-key solution. We have built the broiler, breeder, layer and free range facilities that have become the industry benchmark.

Specification:

Project Name | Poultry Breeder House |

Dimention | Length and width, roof and eave height, roof pitch, etc |

Columns and Beams | Hot rolled or welded H section steel, square tube; paint and galvanized |

Purlin | Galvanized C / Z section |

Support / Brace | Q235 angle steel, round bar and steel pipe |

Tie bar | Q235 steel pipe |

Roof | Corrugated steel sheet with insulation or sandwich panel |

Wall | Wire mashed with curtain system or sandwich panel |

Door and Window | PVC or Aluminum alloy; sliding door or rolled door |

Local Climate | 1.wind speed |

Drawing | 1. according to clients' drawing |

2. design as per your dimension or the birds' quantity you want to feed. | |

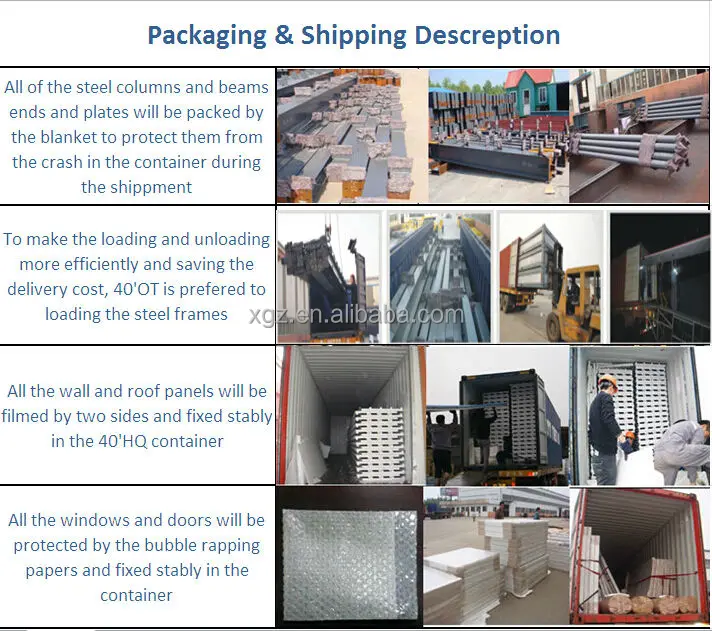

Package | Naked loaded in shipping container or as per requests. |

Loading | 20 GP, 40HP, 40 GP, 40 OT |

Poultry Breeder House function introduction:

1. Main feeding system

This system is consist of silo, hopper, feed pipe, auger, drive motor, feed sensor, ect. This system delivers feed from the silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line which control the motor on and off automatically to release automatic delivery.

2. Automatic pan feeding system

This system includes feed box, drive motor, feed pipe, auger, feed sensor, feed pan, ect. This system deliver feed to the feed pan automatically through motor under the control of feed sensor, which ensure birds feeding during whole growing period.

3. Automatic nipple drinking system

This system can provide fresh and clean water for poultry which is crucial for the growth of

Poultry. The drinkers can be triggered from 360 degree which helps young birds start well and

makes drinking easier. It has pressure regulator, water pipe, support tube, nipple drinking ect.

4. Automatic ventilation system

This system controls climate conditions, fresh air, humidity and temperature in poultry shed, it

is vital for growing birds. This system includes poultry house fan, cooling pad, roof and wall air inlet window.

5. Environment control system

This system saves labor and the resources under the condition of assuring the suitable growth environment of poultry chickens. It is imported from Israel which can set an optimum working mode according to the local climate and raising environment.

Standard container size:

Specification | 20’GP | 40’GP | 40’HQ | 45’HQ | |

Internal Size ( mm ) | Length | 5,898 | 12,032 | 12,032 | 13,556 |

Width | 2,352 | 2,352 | 2,352 | 2,352 | |

Height | 2,393 | 2,393 | 2,698 | 2,698 | |

Volume | CBM | 33.2 | 67.7 | 76.4 | 86.0 |

Weight ( kg ) | Gross Weight | 30,480 | 30,480 | 30,480 | 30,480 |

Tare Weight | 2,180 | 3,650 | 3,830 | 4,700 | |

Max Load | 28,300 | 26,830 | 26,650 | 25,780 | |