High Quality Poultry Farm Equipment Chicken Shed Layer Cage With Auto Drinker And Feeder

Product DescriptionPrefab chicken farm with the main framwork is steel structure, which is composed of Main feeding system, chain feeding system, Nipple drinking system, Ventilation system, Environmental control system, and Spraying system.

Column and Beam:galvanized Q235, Q345 H section steel or square tube

Roof: corrugated steel sheet with insulation or sandwich panel

Wall: Wire meshes with curtain system or sandwich panel

Characters:

1)Easy to assemble and disassemble with simple and common tools.

2) Good waterproof performance without extra facilities.

3) Good fireproof performance with rockwool sandwich panel.

4) Good performance of heat-insulation.

5) Safety and stable,could stand firmly over 50 years.

6) Light weight, convenient for shipment and transportation.

7) Beautiful appearance, various colors and shapes for outer and inner roof panel and wall panel

8) Various designs available, customized designs acceptable.

The size range:

1.chicken house width: 12m-15m

2.length: not longer than 150m

3.the hight: 2.2m-4m

4.13-15 chickens per sq.meter

For example We will raise 20,000 chickens.

we settings the size : 15x135x2.5m

Automatic equipments:

1.Main feed line system

2.Pan feeding system

3.Nipple drinking system

4.Ventilation system

5.Cooling pad system

6.Spraying system

7.Heating system

8.Environment control system

Environment control:

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad is installed on one side of the wall, fan installed other side. When air flow through cooling pads, the water evaporation absorbs a lot amount of heat.

The height of cooling pad is 1.5-2.2m, length about 3m, the area of cooling pad in chicken house is about 6-8 times than the fans.

ventilating system

The main parts of ventilation system is the big fan and small fan. They are controlled by the control system. The NO. of the fans to run was decided by the temperature of the poultry house.

About 200m2 need 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in chicken house.

Picture Show

Our commercial saleused quality glass layer broiler chicken housecompared with the traditional structure of the advantages:

1.big span (6-42 m arbitrarily chosen) without beam purlin, without support, spacious internalclearance is admirable.

2. it cost cheap, economical and practical, roof insulation, heat insulation, ventilation andlighting, sui generis.

3. the construction speed, per million square meters roofing construction can be done in 20 days or so.

4.light weight, long service life: color steel plate light weight is very applicable to buildings add layer and renovation, use period of 50 years.

5. beautiful modelling, colorful (12 colors to choose), unique style, novel and a rhythm, with apermanent waterproof effect of.

We can supply the follow system for chicken farm:

Prefab chicken farm equipments

Feeding systerm Nipple drinking systerm

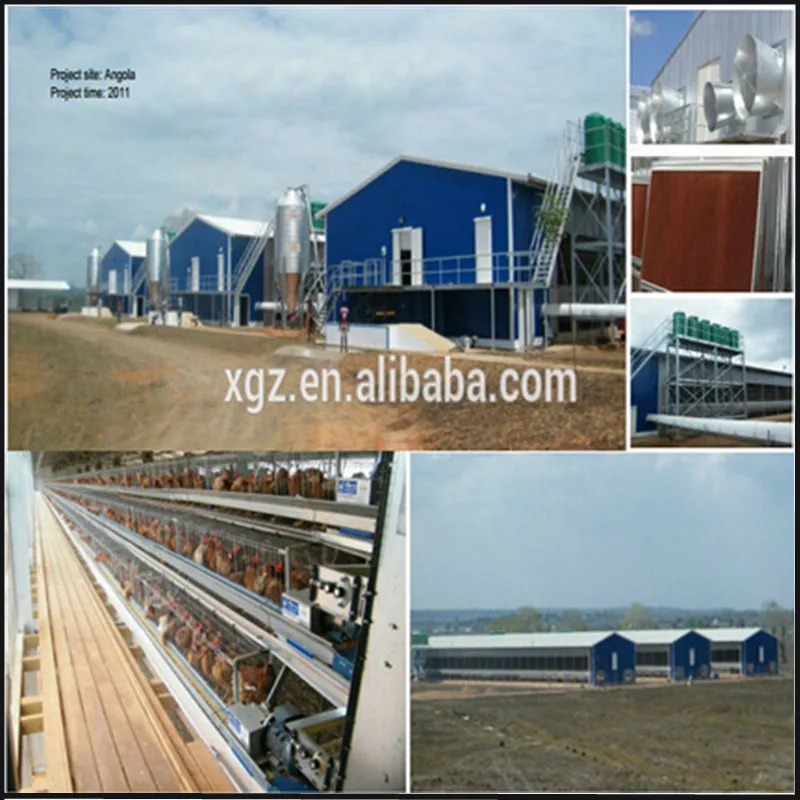

Angola project

Qatar project

Our sample chicken house

Our excellent design team will design the steel structure workshop warehouse for you. If you give the following information, we will give you an satisfactory drawing.

1 Location (where will be built? ) _____country, area

2 Size: Length*width*height _____mm*_____mm*_____mm

3 wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

4 snow load (max. Snow height) _____kn/m2, _____mm

5 anti-earthquake _____level

6 brickwall needed or not If yes, 1.2m high or 1.5m high

7 thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8 door quantity & size _____units, _____(width)mm*_____(height)mm

9 window quanity & size _____units, _____(width)mm*_____(height)mm

We have a professional installation team.If you need, we can provide you guide construction installation.