light steel structure helicopter hangar

we have done many hangar projects inthe past years.So, we have enough ability and experience to do your project well.

Cost Saving

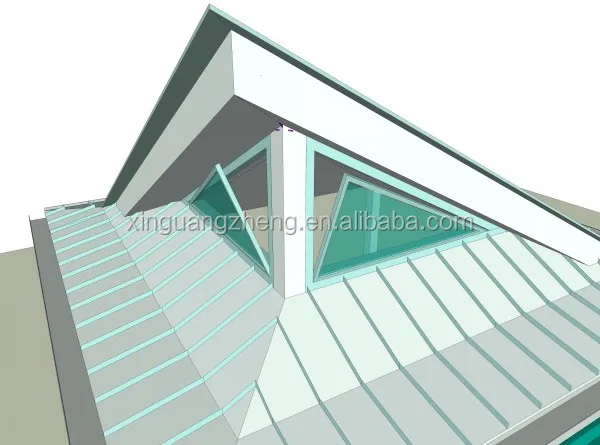

Lower financing costs and earlier access for following trades. Offsite structural steel fabrication facilitating lower site costs during construction and better site utilization. Prefabricated steel building construction allows greater independence from the weather. Low cost and efficient approaches to fire protection.

Advanced Technology

Pre-engineered steel buildings can take advantage of Just-in-time manufacturing techniques. The steel frame of the building is designed and manufactured from computer models directly linked to the CNC machines thus ensuring high dimensional accuracy and speed of erection.

Speed Of Installing

Pre-fabricated steel frame buildings allow off-site manufacture resulting in less site activity. The speed of steelwork erection means inconvenience caused is reduced to a minimum period.

Environment Friendly

Steel is basically a clean, user-friendly material - no dust, no spillage, little waste etc - and consequently no equipment employed to counteract such problems. Steel can be reused, relocated or recycled once its use has been overtaken by events. Use is therefore responsible in environmental terms.

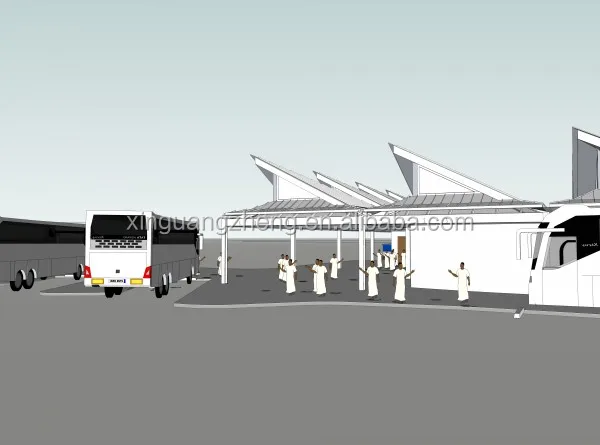

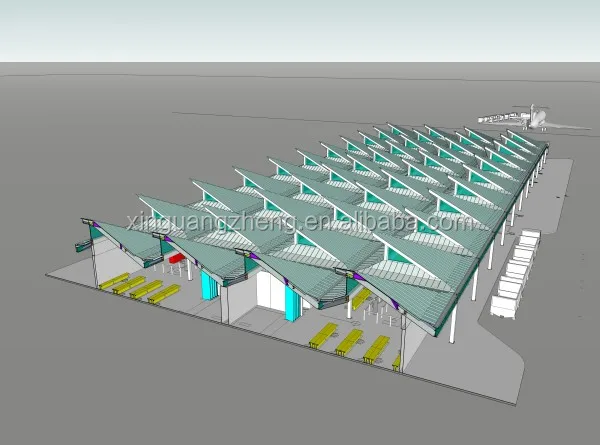

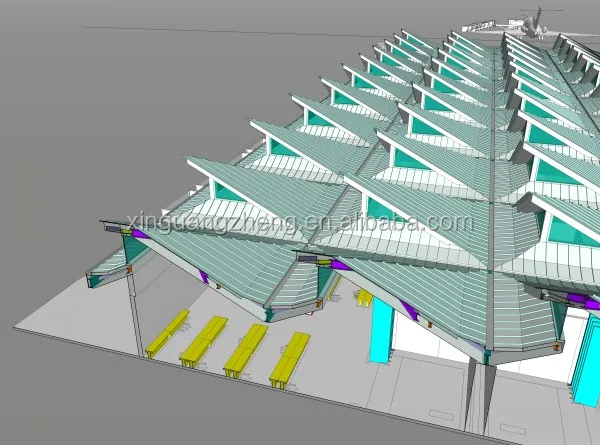

Helicopter hangar projects No.1

Project No.2

Assisted Install

Certification

Quality Standard

Certification | ISO9001:2000,SGS Standard |

Code for design of steel structure | GB 50017-2003 |

Technical code of cold-formed thin-wall steel structure | GB50018-2002 |

Load code for the design of building structures | GB 50009-2006 |

Construction quality acceptance of steel | GB50205-2001 |

Code for design, construction and acceptance of high strength for steel structure | JGJ82-91 |

Technical specification for welding of steel structure building | JGJ 81-2002 |

Technical specification for steel Structures of tall buildings | JGJ99-98 |

Specifications for processing of steel structure | DBJ 08-216-1995 |

Specifications for design and construction of steel panel | YBJ 216-88 |

Quotation Information

In order to give you an exactly quotation and design, please offer us details as follows:

1. Dimensions: Length, width, height.

2. Local weather: Wind speed, rain load, snow load, earthquake strength.

3. Roof and wall insulation system: colored steel sheet or sandwich panel. As for sandwich panels, we can offer

you 4 options( EPS,PU, rock wool, fiberglass).

4. Door and window: position and size

5. Some other requirements.

Customized design is also available.

OUR COMPANY

Company name: | Qingdao Xinguangzheng Steel Structure Co., Ltd. |

Address: | No. 268, Sancheng Road, Pingdu, Qingdao, Shandong, China |

Employee: | 700 |

Main product: | workshop, warehouse, poultry house& shed, hanger, garage, container house, prefabricated house, crane, steel structure materials, sandwich panel |

Main machine | Auto H steel welding machine, cutting machine, sand blasting machine, assembling machine, bending machine, butting machine, corrugated steel sheet machine, assembling machine, CNC automatic fire cutting machine, floor deck machine, H&T steel welding machine, sandwich panel production line, drilling machine, H&T steel welding machine |

Thanks for the visiting! If you are interested in our product, please kindly let us know!