Specifications

factory building design.large span,pre-engineering prefabricated steel structural

2.light or heavy steel

factory building design description:

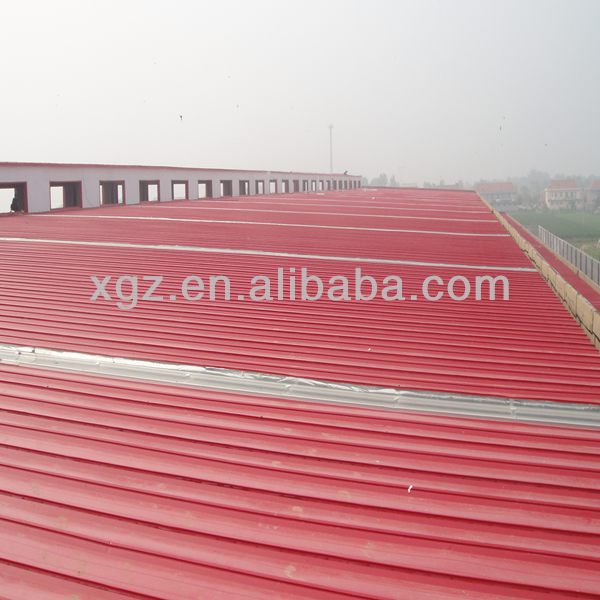

factory building steel structure factory building steel structure is a new type of building structure system, which is formed by the main steel framework linking up H-section, Z-section, and U-section steel components, roof and walls using a variety of panels and other components such as windows and doors. Light steel structure building is widely used in warehouses, workshops, large factories, and so on.

Dimensions | Length | Hbeam:4000-15000mm |

Thickness: | web plate:6-32mm wing plate:6-40mm | |

Height | 200-1200mm | |

Color | according to customers | |

Main components | Main frame | H beam |

Purlin | C or Z section steel purlin | |

Brace | Anchor, ordinary, high strength bolt | |

Bolt | Sandwich panel or steel plate | |

Roof & wall | PVC or aluminum alloy door | |

Door | Sliding or rolling door | |

Insulation panel | EPS, Rock wool , PU sandwich | |

Material | Q235B,Q345B China standard steel | |

Sheet | 0.5mm or 0.6mm galvanized sheet |

2) Materials:

1. The main frame (columns and beams) is made of welded H-style steel.

2. The columns are connected with the foundation by pre-embedding anchor bolt.

3. The beams and columns, beams and beams are connected with high intensity bolts.

4. The envelop construction net is made of cold form C-style purlins.

5. The wall and roof are made of color steel board or color steel sandwich panels, which are connected with the purlin by Self-tapping nails.

6. Doors and windows can be designed at anywhere which can be made into normal type, sliding type or roll up type with material of PVC, metal, alloy aluminum, sandwich panel and so on.

3) Characteristics:

1. Wide span: single span or multiple spans, the max span is 36m without middle column.

2. Low cost: Unit price range from USD35/m2 to USD70/m2 according to customers' request.

3. Fast construction and easy installation.

4. Long using life: up to 50 years.

5. Easy construction, time-saving, and labor saving

6. Flexible layout, beautiful appearances, and higher space efficiency

7. Be used as warehouses, workshops, shopping mall, dinning hall, stadium, etc.

5. Others: environmental protection, stable structure, earthquake proofing, water proofing, and energy conserving.

4) How to build a factory building steel structure ?

You should give us the following data:

Design Data | 1.live load on roof(KN/M2) 2.wind speed(KM/H) 3.snow load (KG/M2) if have 5.crane (if have), lift height, lift capacity, |

Size | 1.width 2.length 3.eave height 4.roof slope |

Type | 1.single slope OR double slope 2.muti slope OR single span 4.single floor OR two floors |

Intercolumn | 5m, or 6m…. |

Windows &Door | 1.quantity 2.size 3.Location 4.PVC or aluminum |

Column &Beam | straight cross-section OR Variable cross-section |

Roof & Wall Panel | 1.colorfull corrugated steel sheet 0.326~0.8mm thick ,YX28-205-820(820mm wide), |

Purlin | 1.C purlin size:120~C320,Z 2.purlin size100~Z200 |

Accessories | Do you need the skylight belts, Ventilators, down pipe, out gutter etc? |

Surface Treatment | Shot blasting with anti rust paint or hot dip galvanize |