Chicken egg poultry farm

1. Column: galvanized Q235, Q345 H section steel or square tube

2. Beam: galvanized Q235, Q345 H section steel or square tube

3. Purlin: Galvanized Q235 C channel

4. Vertical and transversal support: Q235 angle steel, round bar or steel pipe.

5. Tie bar: Q235 steel pipe

6. Brace: Q235 round bar

7. Sleeve: Q235 steel pipe

8. Roof: corrugated steel sheet with insulation or sandwich panel

9. Wall: Wire meshes with curtain system or sandwich panel

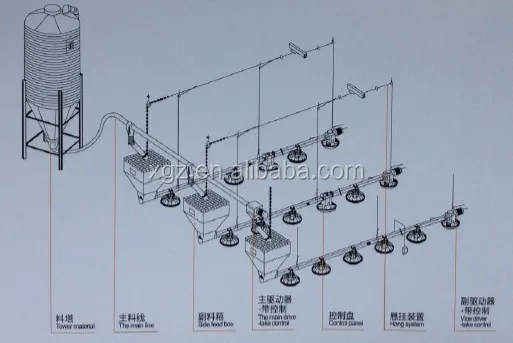

10. Feeding system: feeder motor connect with feeder hopper

11. Nipple drinker system

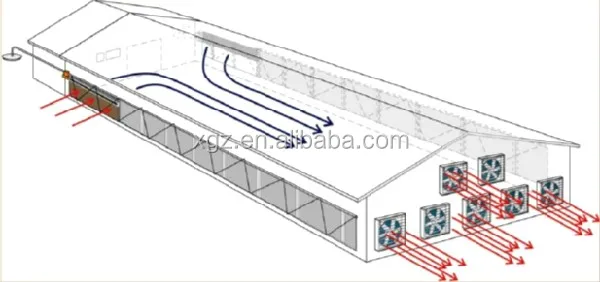

12. Tunnel ventilation and heating system

13. Curtain system: automatic curtain machine

14. Suspension system with ceiling winch

15. Ventilation: external damper fan with cone

1. Description:

Chicken house is composed of Main feeding system, chain feeding system, drinking system, ventilation system, environmental control system, and Spraying system.

Main frame is steel structure,e.g. column,beam:galvanized Q235, Q345 H section steel or square tube

Purlin:galvanized C section steel

Roof: corrugated steel sheet with insulation or sandwich panel

Wall: Wire meshes with curtain system or sandwich panel

2 Characteristics:

1.rust protection, acid resistance, good insulation performance.

2.easy installation, high efficiency, lower cost, great flexibility.

3.wind protection, lighting and shock protection,environment friendly.

3.ference range:

1.chicken house width: 12m-15m

2.length: not longer than 150m

3.the hight: 2.2m-4m

4.13-15 chickens per sq.meter

For example We will raise 20,000 chickens.

we settings the size : 15x135x2.5m

4. Automatic equipment show

1.Main feed line system

2.Pan feeding system

3.Nipple drinking system

4.Ventilation system

5.Cooling pad system

6.Spraying system

7.Heating system

8.Environment control system

The function of deliver system is to transmit the feed outside shed to the hopper of feeding system inside, control system indicates delivery system to work automatically.

Feed of poultry raising farm is stored in the silo, so as to save large amount of package, and also to ensure the health of feed. Different specifications of silos are alternative to choose according to the daily consumption and the size of poultry house. Material of silo consist of galvanized sheet and glass fiber reinforced plastic.

The core of feeding system. Feed in the hopper is delivered by the motor, through delivery pipe to fullfill feed pans one by one. When all of the feed pan are all of feed, control box will stop the motor from working.

The length of one feed line will not longer than 150m, so the length of chicken house can’t be longer than 150m. This is the important thing to concern when design the size of the chicken house.

The distance between 2 feeding line is about 4m. This is also the important thing to concern when design the size of chicken house.

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad is installed on one side of the wall, fan installed other side. When air flow through cooling pads, the water evaporation absorbs a lot amount of heat.

The height of cooling pad is 1.5-2.2m, length about 3m, the area of cooling pad in chicken house is about 6-8 times than the fans.

ventilating system

The main parts of ventilation system is the big fan and small fan. They are controlled by the control system. The NO. of the fans to run was decided by the temperature of the poultry house.

About 200m2 need 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in chicken house.

We can provide the quotation , if you confirm the information as bellow:

*Wind speed(KM/H)

*Snow load (KG/M2)

*Rain load (KG/M2)

*Earthquake load if have

*Demands for doors and windows

which kind of chickens will you feed?And how many chickens will you plan to feed?

Qingdao Xinguangzheng Steel Structure Co. Ltd | |

A. Main Steel Structure | |

1 | Galvanized Steel Framework |

2 | Foundation Bolt |

B. Support | |

1 | Galvanized C Purlin |

2 | Roof Support |

Support between Column | |

C. Roof | |

1 | Roof Panel |

2 | Ridge Tile |

3 | Fastigium sheet & Eave trim coverage |

4 | Other accessories |

D. Gable Wall | |

1 | Gable Wall Panel |

2 | Gable corner covered sheet |

3 | Flashing sheet |

E. Fastener | |

1 | Galvanized Bolt |

2 | Self-tapping Screw |