Specifications

pre engineered galvanized steel workshop sheds buildings

2.Endurable with up to 50 Years

3.Environmentally Friendly

4.Nice Appearance

pre engineered galvanized steel workshop sheds buildings pre engineered galvanized steel workshop sheds buildings Description:

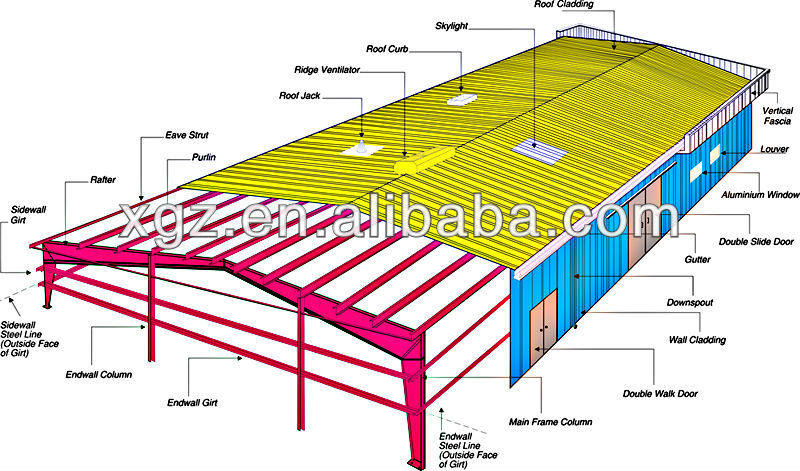

pre engineered galvanized steel workshop sheds buildings pre engineered galvanized steel workshop sheds buildings Description:Light steel structure workshop shed is a new type of building structure system, which is formed by the main steel framework linking up H-section, Z-section, and U-section steel components, roof and walls using a variety of panels and other components such as windows and doors. Light steel structure building is widely used in warehouses, workshops, large factories, and so on. Steel structure is strong, environmental protection, heat preservation, waterproof and soundproof. They are very popular nowadays.

pre engineered galvanized steel workshop sheds buildings Advantages:

1) Easy to assemble and disassemble with simple and common tools.

2) Good waterproof performance without extra facilities.

3) Good fireproof performance with rock wool sandwich panel.

4) Good performance of heat-insulation.

5) Safety and stable, could stand firmly over 50 years.

6) Light weight, convenient for shipment and transportation.

7) Beautiful appearance, various colors and shapes for outer and inner roof panel and wall panel.

8) Various designs available customized designs acceptable.

9) Wide range of application could be used as offices, command posts, sentry boxes, dormitories, workshops, Kiosks and so on.

pre engineered galvanized steel workshop sheds buildings Material:

1. The main frame (columns and beams) is made of welded H-style steel.

2. The columns are connected with the foundation by pre-embedding anchor bolt.

3. The beams and columns, beams and beams are connected with high intensity bolts.

4. The envelop construction net is made of cold form C-style purlins.

5. The wall and roof are made of color steel board or color steel sandwich panels, which are connected with the purlin by Self-tapping nails.

6. Doors and windows can be design according to your drawing (paper graph)

Main frame: welded steel, Q345

Column&beam:C purlin, H purlin Q235

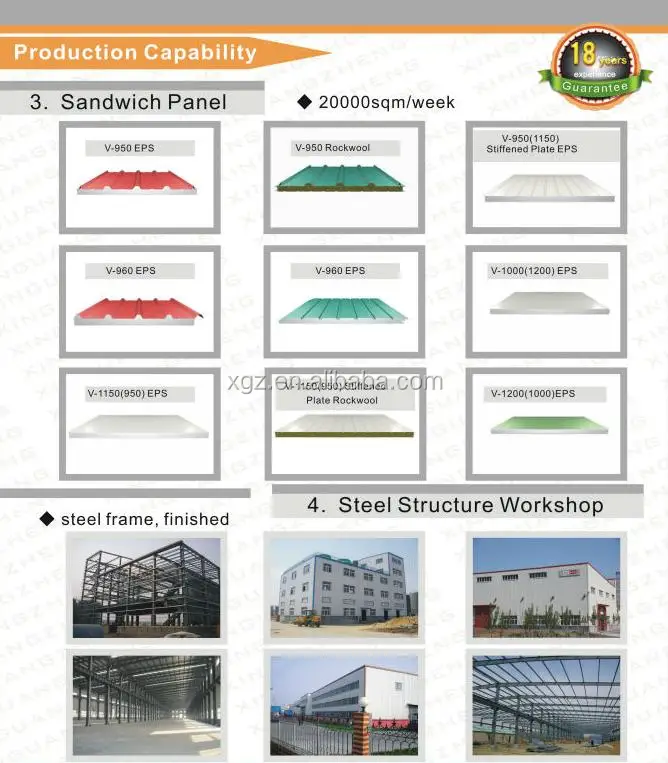

Wall&Roof: EPS, Rockwall, PU sandwich, corrugated steel sheet

Door: Rolled up door or Sliding door (sandwich panel door)

Window:Plastic steel or Aluminum alloy window

pre engineered galvanized steel workshop sheds buildings processing equipments:

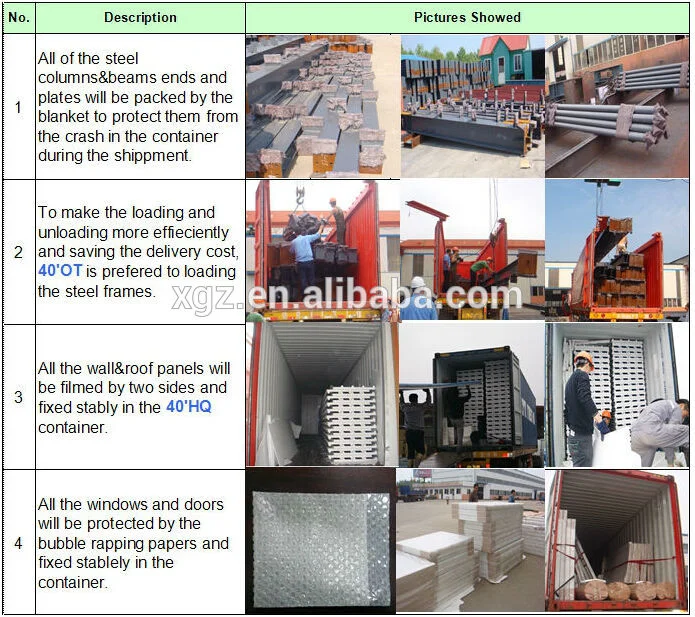

pre engineered galvanized steel workshop sheds buildings packaging and shipping:

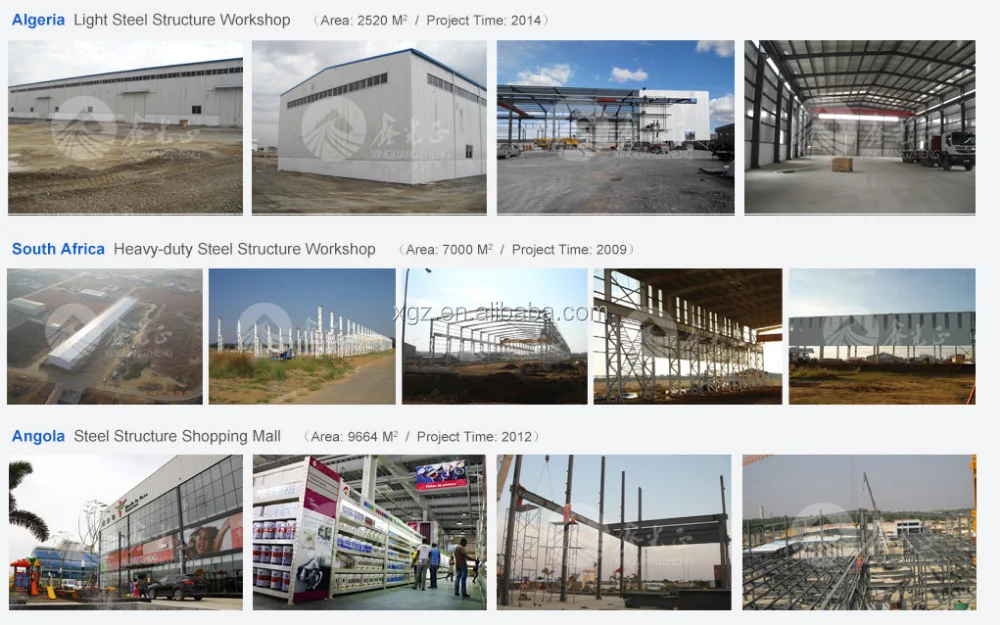

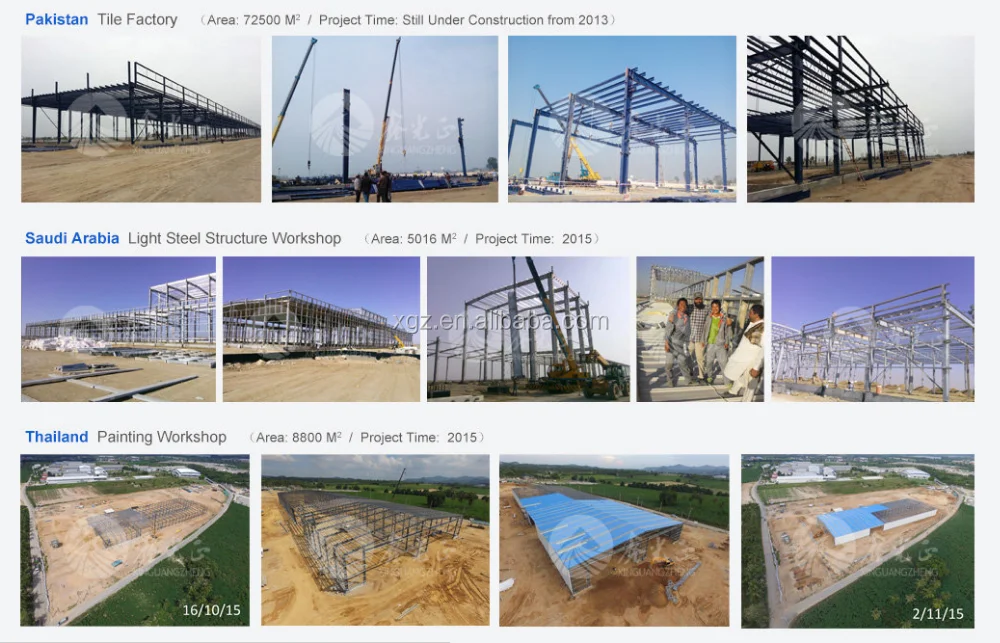

Projects Showcase

Applications:

Steel workshop/warehouse/shed, Exhibition Hall, Office buildings, Garage, Multi-storey building, Hanger, Agricultural storage, Logistic centers, and all kinds of steel materials, etc

Exported countries:

Gabon, South Sudan, Japan, United States, Ivory Coast, Uganda, Egypt, Russia, The republic of Belarus, Germany, Sweden, Argentina, New Zealand, Australia, Turkmenistan, etc.

Tips for inquiry:

- The length, width, height of the building

- the height from the eaves to the ridge

- the local environment( working condition), for example: rain, wind or snow condition

- the local geological conditions(ground roughness condition)

Remarks:

We can supply the materials and accessories as well as do the design as customers’ request.

Our price is competitive, as we are a manufacturer, the direct source; this is the advantage of us. We guarantee the best service and quality.