Comfortable low cost prefabricated steel frame house is a new type of building structure system, which is formed by the main steel framework linking up section steel components, roof and walls using a variety of panels and other components such as windows and doors etc.

Product description

Main structure

Dimention: Flexible size for 30 - 250 square meters.

Main column: Q235 square tube 80*80, 100*100, 120*120, 150*150mm

Main truss beam: Q235 C80, C100, C120, C140 section steel

Wall and roof purlin: Q235 C80, C100, C120, C140 section steel

Floor

Groud floor will be the concrete foundation with Ceramic tiles or PVC floor leather

First floor: 18mm plywood with 2.0mm PVC floor leather for living rooms floor

Ceiling

6mm Gypsum board for dry room

12mm PVC ceiling for wet room

Walls

Insulated Steel Sandwich Panel wall

Panel width: 950mm

Thickness: 50/60/75/90/100/120mm

Color coated steel on both sides: 0.4mm/0.5mm/0.6mm

Insulation: Polyurethane (EPS), Fiberglass, Rockwool, Polystyrene (PU)

Kg/m3,

Density of Fiberglass: 60Kg/m3

Density of Rockwool: 120Kg/m3

Density of Polyurethane: 40Kg/m3

Door

External door: Insulated with opening dimension 950*2100mm, furnished with lock

with 3keys. Inner door: Insulated steel door.

Windows

Window material: PVC , Plastic steel, Aluminium alloy window siding or opening.

Electrical fittings option

Electrical wire, 2.5 mm2 for lighting system, and 4mm2 for AC units.

16A five hole universal socket.

double tube fluorescent lamp, 220V,50-60HZ

Single Switch, with junction box

Electrical distribution box, box + breakers + earth leakage protective device

Optional Water system fittings

Water drain pipe, PPR pipe, dim 16-20mm, connection fittings are made of copper, life span over 10 years.

Exhaust fan or air exchange hole, size 250mm*250mm made of steel or PVC

Sanitary ware:

Western Close tool: ceramic, with pipes and installation fittings

Urinal: ceramic, with pipes and installation fittings

Wash basin: ceramic, with post, faucet, pipes and installation fittings

Shower head, Shower base, Water mixture

Features

• Highest quality metal and components • Solid steel frame construction

• Full Frame on Door and window Openings • Galvalume finish panel

• Pre-Cut Pre-Drilled • Anti-rust fasteners

• Weather protection • 100% Recyclable Steel

• Weather proof • Virtually Maintenance Free

• Diverse layout and dimention • Easy and fast assembly

Advantages

1. Attractive design ----beautiful and elegant looks, use the color steel sandwich panel, the material is polystyrene foam.

2. Easy to assemble and dismantle -----can be rebuilt for dozens of time with plugs and screw.

3. Firm structure----steel frame structure and sandwich panels

4. Durable----the steel frame parts are all processed with anti-corrosion coating and can be used for as long as 30 years.

5. Reduce cost by integrating &manufacturing &service processes.

6. With reliable quality and efficient service Offer one-stop service from developing, design, manufacturing to installation

7. Sizes and design are according to requirements.

Packaging & Shipping

Wy choose us

1. Quality Gurantee

High strength, light weight, good material, high reliability and fast installation high level of industrialization.

2. Capacity of engineer

* More that 80 professional technicians and qulified R&D Engineers.

*Based on the concept of modern design and corresponding national standards

*Most optimized design high-efficiently with the use of advanced internal aid design software, such as PKPM and 3D3S

*Complete set of production and installation drawings of steel structure to ensure the high-efficient and accurate operation.

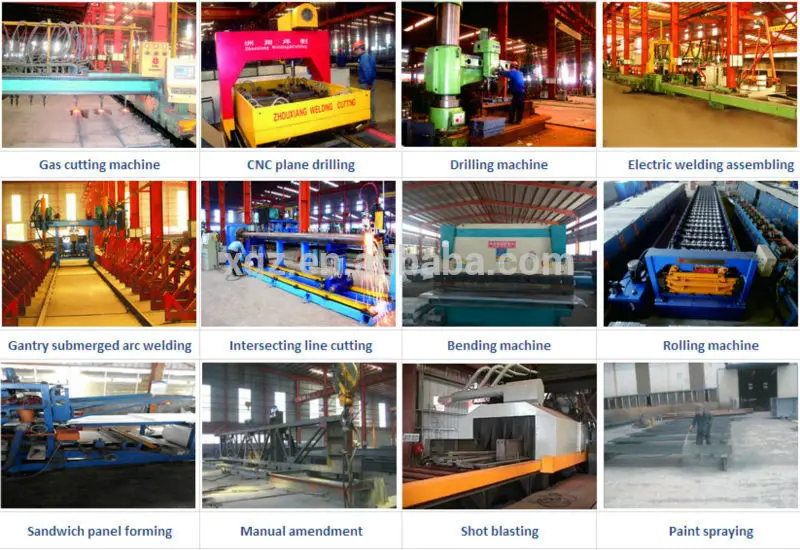

3. Production capacity

*700 workers, 60000 m2 workshop, 18 years’ experience, ISO&BV&SGS certificated, one hour reach Qingdao port.

*Own light/heavy H steel production line, BOX production line ,C/Z purlin production line and various types of profiling steel sheet machines.

*The annual production capacity: main steel structure 40000mts,secondary steel25000mts, various profiling steel sheet 500000 sqm annual.

4. Our design, manufacture and installation experience

*18 years of accumulation and exploitation.

*Formed our own complete set of building system for wall and roof of steel structure .

*Rich experience in waterproof and insulation technology. Support quality assurance of our clients.

FAQ1. Q: Order process?

A: . Floor plan layout - Confirmation of building materials - Specific quotation - Place the order - Shop drawings - Manufacture - Shipping - Installation

2. Q: How to pay?

A: T/T - 30% deposit in advance, 70% balance before shippment. OR L/C At sight.

3. Q: What is the delivery time?

A: Generally speaking, the delivery time will be within 15 - 30 days.

4. Q: How to deliver?

A: Delivered by 40ft GP / HQ / OT Shipping containers.

5. Q: How to install?

A: We will provide detailed illustration photos and videos to you. If it is necessary, we will send professional engineers to do the constructuion guidance, and some skilled workers to help installation. However, the visa fee, air tickets, accommodation, wages will be borne by buyers.

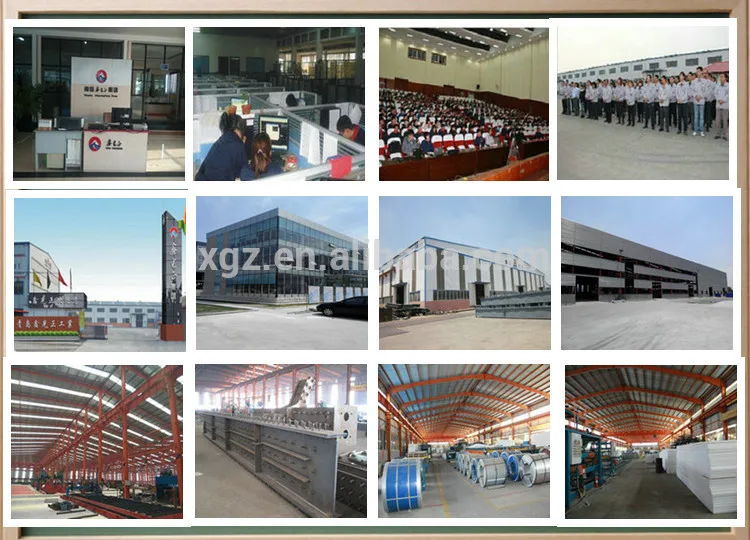

Company Information

Qingdao Xinguangzheng Steel Structure Co.,Ltd specializes in designing, modeling, manufacturing and installing steel structure buildings in all aspects of residential, industrial and commercial field abroad and domestic. More than 300 foreign companies from all over 75 countries and regions have established cooperation relationship with us. Our professional teams will always bring best solutions to the projects that allow the buildings to finish on time and within budget. We are looking forward to establishing mutual business relationship with your esteemed company.

Production Line

Certifications --- ISO9001, BV and SGS

Customers with us

Our buldings have been supplied to South Africa, German, Sudan, Norway, Slovenia, Ethiopia, Uruguay, Mali, Algeria, Paraguay, Argentina, Russia, Kenya, Australia, Ghana, Saudi Arabia, Angola,,,etc.

Looking forward to your inquiry in early day, your satisfaction will be our everlasting pursue.