2014 eco friendly lightweight construction material sound heat insulated eps cement sandwich panel ( for prefabricated house)

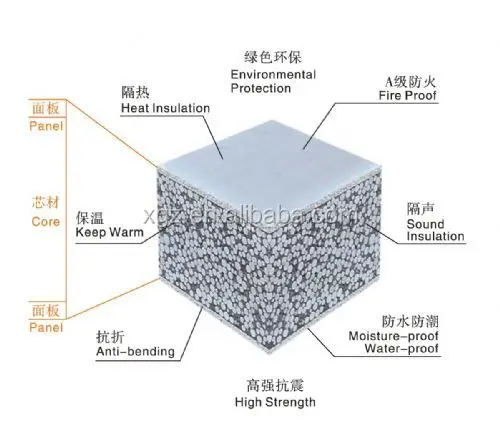

1.Energy Saving, Excellent Performance

Heat Preservation: Major material for wall panel is anti-freezing, heat preserving and environmental friendly.

Heat Insulation: Adjust the indoor temperature at a constant range.

Fire Proof: Both face sides with 4.5mm calcium-silicon fire proof board, thus XGZ Eps and Cement sandwich panel can be against a high temperature of 1000°C for 4 hours.

Water Proof: Tests has proved that water containers can be made by XGZ Eps and Cement sandwich panel without absorbing functions and no leakage at all.

Sound Insulation: The inside of XGZ wall panel material (EPS polystyrene grain) has fine sound insulation and sound-absorbing functions.

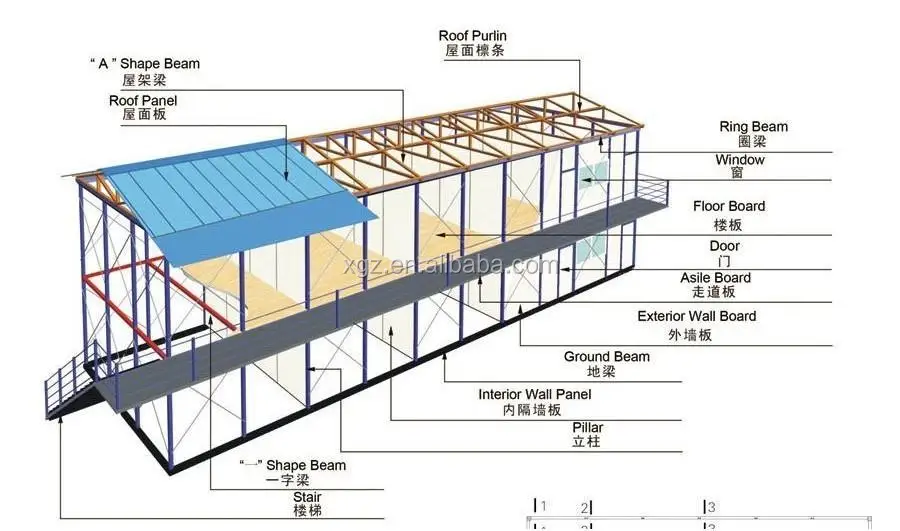

2. Easy Construction Process

Easy to Install: Using our installation material (PU Foam and Cement Adhesive) is easy to build house

Shorter Time: For a 50sq. house, using XGZ Eps and Cement sandwich wall panel, three people can finish it within ONE day, while using traditional block, it will take at least SEVEN days with ONE WEEK to finish.

3. High Security performance

High Intension: XGZ Eps and Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies, it can be covered by ceramic tile, wall paper, wood panel, coating etc.

Earthquake Resistance: The Seismic performance of DQ Eps and Cement sandwich wall panel is at a magnitude of 8.5.

4.Space and Cost Saving

Space Saving: XGZ Eps and Cement sandwich wall panel with the thickness of 60mm-180mm, as a thin and solid new type construction material, it will save a lot of construction space compared with the traditional block.

Labor Cost Saving: As XGZ wall panel is easy and fast to construct.

Foundation Cost Saving: As the weight of XGZ wall panel is only 1/12 of traditional block, it will save 2/3 cost on construction structure

| Name | Weight Compound Sandwich Panel | ||||||

| Thickness(mm) | 60 | 75 | 90 | 100 | 120 | 150 | 180 |

| width(mm) | 610 | 610 | 610 | 610 | 610 | 610 | 610 |

| length(mm) | 2270 / 3000 | 2270 / 3000 | 2270/ 3000 | 2270/ 3000 | 2270/ 3000 | 2270 /3000 | 2270/ 3000 |

Composition:

1. Calcium silicate board(face panel)

2. Cement and EPS(core material)

3. Calcium silicate board(face panel)

Application:

Assembly houses, villas, public buildings, commercial buildings, residential houses, firewall, fire-rated warehouse, cold storage, etc.

EPS cement Sandwich panel can work as substitute of traditional construction materials such as brick, hollow brick etc

(1) Floor system

(2) Roof system

(3) Interior & Exterior wall system

(4) Villa Wall system

FAQ:

Q: What are the advantages of your EPS cement sandwich panel?

A: Our panel's outstanding advantage are light weight, heat insulation, waterproof, fireproof,sound insulation, fast construction and so on.

Q: Is the panel fire rated, if so, what is the rating?

A: Theoretically, it can endure the fire for 4 hors in the heat of 1000c. But in fact, it is incombustible.

Q: Do you have any certificate to help us get government's approval?

A: We can supply our ISO certificate, test report, SGS certificate as your support document. Since thebuilding standards are different in various countries, most of our customers buy the panels for test and get approval by themselves.

WELCOME TO VISIT XGZ GROUP!