eps cement sandwich panel lightweight external wall

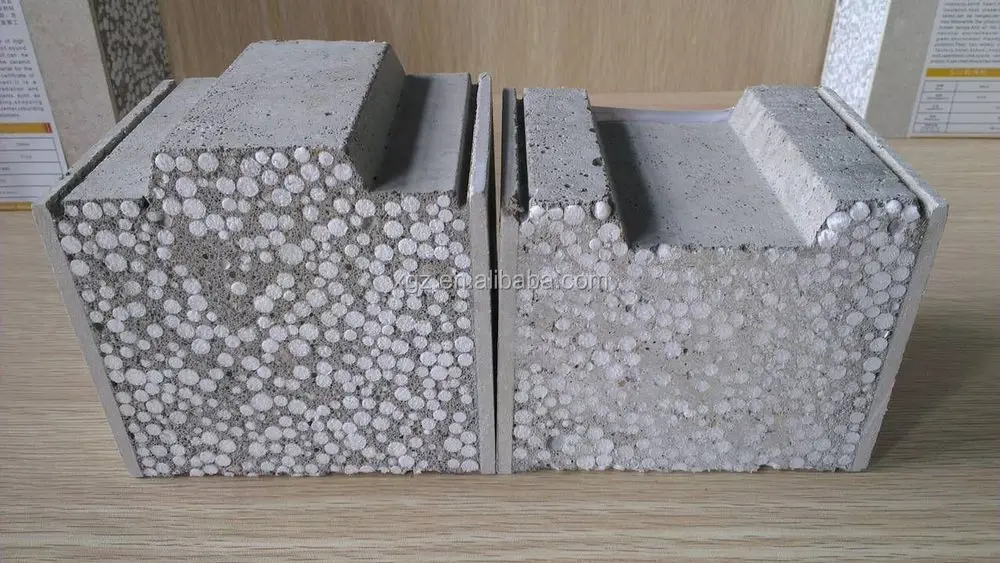

Eps cement sandwich panel is a kind of lightweight energy saving wall material, which used cement calcium silicate or reinforced calcium silicate board as face panel, filled with cement,eps polystyrene foam particles and forming by one time compound.

Light weight fiber cement panel advantages:

1. Light weight:

Its density is only 750-800kg/m3, and the weight of 75mm thick wall panel is 60kg/m2, which is only 1/6 of that of brick walls, 1/2 of that of aerated concrete, and 1/7 of that of 120mm thick masonry wall with plastering on both sides.

2. Fire proofness:

It can endure fire at 1000 degrees for over 4 hours, without producing any toxic gas. Its incombustibility meets A rating of the state standard.

3. Water-proofness & Damp-proofness

It consists of medium density fiber cement flat board, which has very good water proof and damp proof property. Therefore, there is no worry about bulking, efflorescence, deformation, degeneration of strength due to moisture absorption. It's applicable for wet areas like kitchens, bathrooms and basements.

4. Sound Insulation

It has outstanding sound absorption and insulation capacity. The sound insulation capacity of a 90mm thick board is 42dB, which is far higher than that of other masonry walls, and meet the national requirement of sound insulation for residential houses.

5. Thermal Insulation & Heat Insulation

Nowadays, the construction industry attaches great importance to energy-saving property of buildings. Ionic strip-type wall panel is made of pure natural vermiculite, quartz flour of high purity, inorganic fibre and plant fiber, through a curing process with steam of high temperature and high pressure. In addition, the internal alveolate structure also contributes to its remarkable thermal insulation & heat insulation property.

6. Better earthquake resistance and overall stability:

Assembled into a whole structure, wall panels has an impact resistant capacity which is 1.5 times as high as that of normal masonry walls. The earthquake resistances is tens of times higher than normal masonry walls, meeting the requirement for buildings to resist earthquake of up to 8 degrees.

7. Easy installation:

The wall panel can be grooved freely, nailed directly or embedded with expansion bolts to hang heavy things, like A/C; The single-point hanging strength is over 45kg; In addition, the wall panel has a flat and smooth surface, which is compatible with tiles and wall paper as the finish.

| Thickness(mm) |

| Width | Reference | Error Allowance (kg/m) |

60 series | 60mm | 2270 | 610 mm | 43± 5 | Length± 5 |

75 series | 75mm | 50± 5 | |||

90 series | 90mm | 55± 5 | |||

12 series | 120mm | 67± 5 | |||

15 series | 150mm | 85± 5 | |||

Customization available according to the customers' need | |||||

. Advantage of pu roof sandwich panel

1.Energy Saving, Excellent Performance

Heat Preservation: Major material for wall panel is anti-freezing, heat preserving and environmental friendly.

Heat Insulation: Adjust the indoor temperature at a constant range.

Fire Proof: Both face sides with 4.5mm calcium-silicon fire proof board, thus DQ Eps and Cement sandwich panel can be against a high temperature of 1000°C for 4 hours.

Water Proof: Tests has proved that water containers can be made by DQ Eps and Cement sandwich panel without absorbing functions and no leakage at all.

Sound Insulation: The inside of DQ wall panel material (EPS polystyrene grain) has fine sound insulation and sound-absorbing functions.

2. Easy Construction Process

Easy to Install: Using our installation material (PU Foam and Cement Adhesive) is easy to build house

Shorter Time: For a 50sq. house, using DQ Eps and Cement sandwich wall panel, three people can finish it withinONE day, while using traditional block, it will take at least SEVEN days with ONE WEEK to finish.

3. High Security performance

High Intension: DQ Eps and Cement sandwich wall panel can be nailed directly or have expansion bolt to lift and hang heavies, it can be covered by ceramic tile, wall paper, wood panel, coating etc.

Earthquake Resistance: The Seismic performance of DQ Eps and Cement sandwich wall panel is at a magnitude of 8.5.

4.Space and Cost Saving

Space Saving: DQ Eps and Cement sandwich wall panel with the thickness of 60mm-180mm, as a thin and solid new type construction material, it will save a lot of construction space compared with the traditional block.

Labor Cost Saving: As DQ wall panel is easy and fast to construct.

Foundation Cost Saving: As the weight of DQ wall panel is only 1/12 of traditional block, it will save 2/3 cost on construction structure.

WELCOME TO XGZ GROUP!