Parts of the Project

1. Column: Q235, Q345 welding H section steel

2. Beam: Q235, Q345 welding H section steel

3. Purlin: Q235 C section or Z section

4. Knee brace: Q235 angle steel

5. Vertical and transversal support: Q235 angle steel, round bar or steel pipe.

6. Tie bar: Q235 steel pipe

7. Brace: Q235 round bar

8. Sleeve: Q235 steel pipe

9. Cladding system: Sandwich panels (EPS, PU, Fiber glass wool etc. ) or can use corrugated steel sheet with fiber glass wool insulation and steel wire gauze.

10. Second floor: Floor deck

11. Second floor office: Fiber cement board floor panel or checkered steel plate

12. Stair: Q235 steel structure with checkered steel plate

13. Door: Sandwich panel sliding door or roller door

14. Windows: PVC or Aluminum

15. Gutter: Stainless steel or color steel sheet

16. Rainspout: PVC

| Product Name | Steel structure workshop,warehouse, shed,prefab house |

| Material | Q235 Q345 steel structure |

| Color | customized by customer |

| Standard | GB ISO CE |

| Brade | Rock |

| Used | Steel structure buildings |

Steel frame

Include Steel Column, Beam.Purline(C/Z), tie bar etc.Surface will be painted or galvanized.

Roof and wall panel

Including Sandwich panel (EPS/ Rock wool/fiberglass),corrogated steel sheet (V-840.V-820,V-960,V-950,V-470,etc)

1) Design according to customer's requirement.

2) Manufacture with high quality control.

3) Engineer helps to instruct installation

1. Quality Gurantee

High strength, light weight, good material, high reliability and fast installation high level of industrialization .

2. Capacity of engineer

* More that 80 professional technicians and qulified R&D Engineers.

*Based on the concept of modern design and corresponding national standards

*Most optimized design high-efficiently with the use of advanced internal aid design software, such as PKPM and 3D3S

*Complete set of production and installation drawings of steel structure to ensure the high-efficient and accurate operation

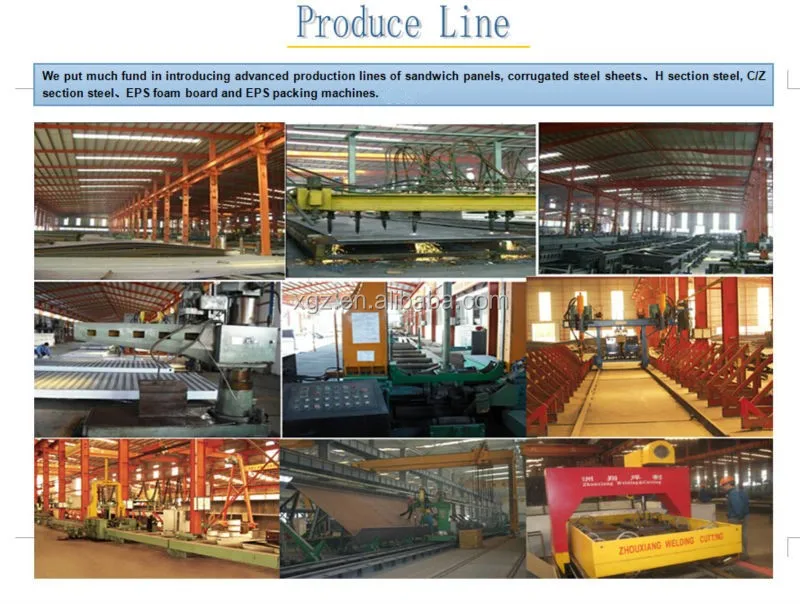

3. Production capacity

*700 workers, 60000 m2 workshop, 18 years’ experience, ISO&BV&SGS certificated, one hour reach Qingdao port.

*Own light/heavy H steel production line, BOX production line ,C/Z purlin production line and various types of profiling steel sheet machines.

*The annual production capacity: main steel structure 40000mts,secondary steel25000mts, various profiling steel sheet 500000 sqm annual

4. Our design, manufacture and installation experience

*18 years of accumulation and exploitation.

*Formed our own complete set of building system for wall and roof of steel structure .

*Rich experience in waterproof and insulation technology. Support quality assurance of our clients.

Packing Details : Packing, solid bicycle saddle, 50pcs/carton

Delivery Details : 3-30 days after order of Solid bicycle tire tubes

1. packing of main steel structure2. packing of main steel structure

1. packing of main steel structure2. packing of main steel structure3. put the packing into container

4. packing of sandwich panel5. panel in container6. z section purline

4. packing of sandwich panel5. panel in container6. z section purline

7 c section purline

8 floor deck

9 corrugated steel sheet

10 casing pipe

11 knee brace

12 base bolts

1.Location (where will be built?)_____country, ___area

2.Size: length*width*height_____mm*_____mm*_____mm

3.wind load (max. wind speed)_____kn/m2, _____km/h, _____m/s

4.snow load (max. snow height)_____kn/m2, _____mm

5.anti-earthquake_____level

6.brickwall needed or not .If yes, 1.2m high or 1.5m high

7.thermal insulation .If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested;

if not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8.door quantity & size _____units, _____(width)mm*_____(height)mm

9.window quanity & size_____units, _____(width)mm*_____(height)mm

10.crane needed or not.If yes, _____units, max. lifting weight____tons; max. lifting height _____m

1. What is steel prefabricated house mean and made of?

RE: Steel prefabricated houses are made of high grade painted steel frame/structure as strong skeleton and lined with sandwich panel as wall and roof, these are pre-designed and manufatured in the factory and later assembled on site.

2. Is it safe and can suit to any kind of stringent weather conditions?

RE: Our houses could resistant earthquake, wind, snow, etc.

3. Can you supply design service?

RE: Yes.also supply design service.

4. What is the payment terms?

RE: a) T/T, 30% deposit and other payment will be payed when you receive the ocean bill.

b) 100% L/C at sight

5. How long is delivery?

RE: Generally, the delivery time of sandwich panel is within 7 days; and 30 days for prefabricated house. The exact delivery time should depend on the quantity and confirm with factories.

CE certification ISO 9001 certifitation

CE certification ISO 9001 certifitation

ISO 3834 welding certification

Our Company

William Young

Project Manager

Qingdao Xinguangzheng Steel Structure Co.,Ltd

Address: NO.268, Sancheng Road, Pingdu, Qingdao, Shandong, China

MP:+86-17806251285

Skype No. : live:2958174739

Whatsapp: +86-17806251285