2016 modular warehouse construction materials

Product DescriptionSince the company was established in September 2000,we have firmly ashered to the concept of honesty, excellence ,and innovation to provide top quality products and perfect services to our customers .By Jul.2014,we have complete d more than 700 projects of various steel structures.Both the final acceptance rate and diretional excellent rate are 100%.In order to meet the requirements of customers, we are willing to provide the trustworthy products to more customers.

1. Opinions

1)We can supply all kinds of steel structures, steel bulding, metal building, modular house,

Steel frame for warehouse, workshop, garage etc, steel beams, other riveting and welding parts.

2)We can also make and develop new parts according to customers' drawings and detailed dimensions.

2. Specifications

1)Size: MOQ is 10m2, width X length X eave height, roof slope

2)Type: Single slope, double slope, muti slope; Single span, double-span, Multi-span, single floor, double floors!

3) Base: Cement and steel foundation bolts

4) Column and beam: Material Q345(S355JR)or Q235(S235JR) steel, all bolts connection! Straight cross-section or Variable

Cross-section!

5) Bracing: X or V or other type bracing made from angle, round pipe, etc

6) C or z purlin: Size from C120~C320, Z100~Z200

7) Roof and wall panel: Single colorfull corrugated steel sheet0.326~0.8mm thick, YX28-205-820(820mm wide),

Sandwich panel with EPS, ROCK WOOL, PU etc insulation thickness around 50mm~150mm, width 950mm or 960mm!

8)Accessories: Semi-transparent skylight belts, Ventilators, down pipe, outer gutter, etc

9)Surfrace: Paint or hot dip galvanize!

10) Packing: Main steel frame without packing load in 40'OT, roof and wall panel load in 40'HQ!

3. Design ParametersIf you need we design for you, pls supply us the following parameter together with detail size:

1)Live load on roof(KN/M2)

2)Wind speed(KM/H)

3)Snow load (KG/M2) if have

4)Earthquake load if have

5)Crane (if have), Crane span, crane lift height, max lift capacity, max wheel pressure

| Item name | Material characteristics | Material Grade | Surface Treatment |

| Anchor bolt | Steel rod M24,M27 | Q235B | |

| Steel Column | H shape,Box,steel pipe,Hot rolled sheet | Q235B,Q345B | Paint or Hot dip galvanized |

| Steel Beam | H shape,steel Truss,Hot rolled sheet | Q235B,Q345B | Paint or Hot dip galvanized |

| Steel Bracing | Steel rod,Steel pipe,Angle steel | Q235B,Q345B | |

| Steel Purlin | C or Z shape, steel purlin Thickness:1.8mm~3.0mm | Q235B,Q346B | Hot dip galvanized |

| External wall panel,Roof panel | Sanwich panel with EPS,Rock wool,Pu,Glass wool | Steel T=0.426~0.8mm,insulation T=50~150mm | Alu-zinc 150g, Fluorocarbon paint |

| Door | Sliding or rolling door | Steel or Aluminum sheet,T=1.0~1.5mm | Paint or Hot dip galvanized |

| Window | alloy-Glass,Alminium alloy-shutter | T=1.0~2.0mm | Alloy |

| Daylighting panel | FRP, T=1.5mm or T=1.8mm | Coefficient of thermal expansion:2.2x10-5/cm/cm/℃ | Light transmittance 85% |

| Ventilator | Turbine ventilator, ventilator along a slope | Steel,stainless steel,PC | Paint or Hot dip galvanized,304 |

| Gutter | Galvanized Steel plate,stainless steel plate | T=2.0mm | Hot dip galvanized,304 |

| Downpipe | PVC pipe,Color steelpipe T=0.5mm | Φ110,160,200 | Paint |

| Bolt | Ordinary, high strength | 10.9S,4.8s | Hot dip galvanized |

1.container of 40'OPEN TOP,inside capacity is 12.01mx2.33mx2.15m,Gross weight of allocation is generally 27.0 tons,volumn is 60m3.

2.container of 40 feet HIGH CUBE:Inside capacity is 11.8m x 2.34m x 2.18m,Gross weight of allocation is generally 22 ton,volumn is 54m3.

3.HC container of 45 feet:Inside capacity is 13.58m x 2.34m x 2.71m,Gross weight of allocation is generally 29 ton,volumn is 86m3.

Qingdao Baorun Steel structure Engineering Co.,Ltd. was eatablished in 2000,and the registered capital of the company is 51.18 million Yuan. Now the company has 5 pressure-type color steel plate production lines,2 heavy steel production lines,1 H-beam CNC secondary processing production line (3D CNC drilling machine,CNC sawing,CNC milling machines,etc.), and 2 Hbeam shot blasting machines, one 4 m wide flat-biasting machine,4 CNC cutting machine sets,8 automatic submerged arc welding machine,1 CNC plant drilling machine and 2 CNC Bending Machine (macimum thickness og 50 mm),2single-arm welder (10m),etc.The annual output of the company is 40000 tons of light steel,50000 tons og heavy steel,with 3million square meters of color plates and completion of the light steel plant 500000 square meters per year.Qingdao Jinmaoyuan Steel Structure Engineering Co.,Ltd.is located in the beautiful scenery of Qingdao Economic and Technological Development Zone, and it covers an area of 70000 square meters ,the construction area is 50000 square meters .

The company has achieved a successful transiton to the production of marine steel platform in 2007!Now the company has become the qualified subcontasctors of Offshore Oil Engineering (Qingdao) Co,Ltd.China National Petroleum Offshore Engineering Co.,Ltd.,Qingdao,Wuhan Shipbuliding Industry Co.,Ltd, and other famous enterprises!

The company has passed the ISO9001 international quality system certification, ISO14001 environmental quality system certification,GB/T28001 Occupation Health and Safety Management System Certification in the industry og construction and installation of steel in Qingdao

Our products is about civil construction,heavy steel structure,stadium,industrial workshop , warehouse building steel structure ,villa ,container house, hanger ,garage,poulty house prefabricated house, with good quality and pretty competitive price.

Certification:

Some visitor:

in South Africa,Libya,Algeria,Ethiopia,Angola,Congo and Romania, we have exported and installed steel warehouse

Bos of excellent quality and most competitive price level,We have exported our steel structure projects and buildings to Africa area only:

a) North Africa:

1.Algeria :3500m2 steel workshop building

2.Libya: 2500m2 steel factory building

3.Angola: 1500m2 steel warehoue building

b)East Africa

1.Ethiopia:3000m2 steel factory building

2.Kenya: 1000m2 steel warehouse

3.Tazania :1576m2 steel warehouse building

4. Tanzania: steel structure truck repairing workshop building

c)West Africa

1.Ghana :8 steel building

2. Nigeria 4 steel structure factory building

d)Middle Africa:

1.Cameroon: 3000m2 steel workshop building

2.D.R.Congo: 1750m2 steel warehouse

e)South Africa

1.Zambia:7296m2 steel warehouse

2.Angola:16000m2 steel workshop building

3.Zimbabwe: 12000m2 steel factory building

4.Angola:4000m2 steel structure workshop building

5.Angola :4360m2 steel structure workshop building

1. Professional design and engineering team:

Full solution for site camp design. We could make the design for whole camp as per your requirement.

2. Procurement and Manufacture for all material for prefabricated building:

We have a professional procurement team to make sure all the materials are with good quality. And our factory operation under ISO/CE/SGS standard, to make sure the fabrication works with high technology.

3. Site management & Installation supervision:

We could send our engineers to help for the installation supervision, you just need to prepare a team which know normal construction works will be OK.

Why you chooses us ?

1.Material:Q235B,Q345B etc.

2.Convenient to take apart and install,simple,convenient and fast installation

3.High-strength , windproof and reliable load-bearing steel structures

4.Excellent water resistance and drainage

5.Highly anticorrosion and dustproof , painted or dip zinc

6.Eco-friendly-highly recyclable and creates minimal raw material waste.

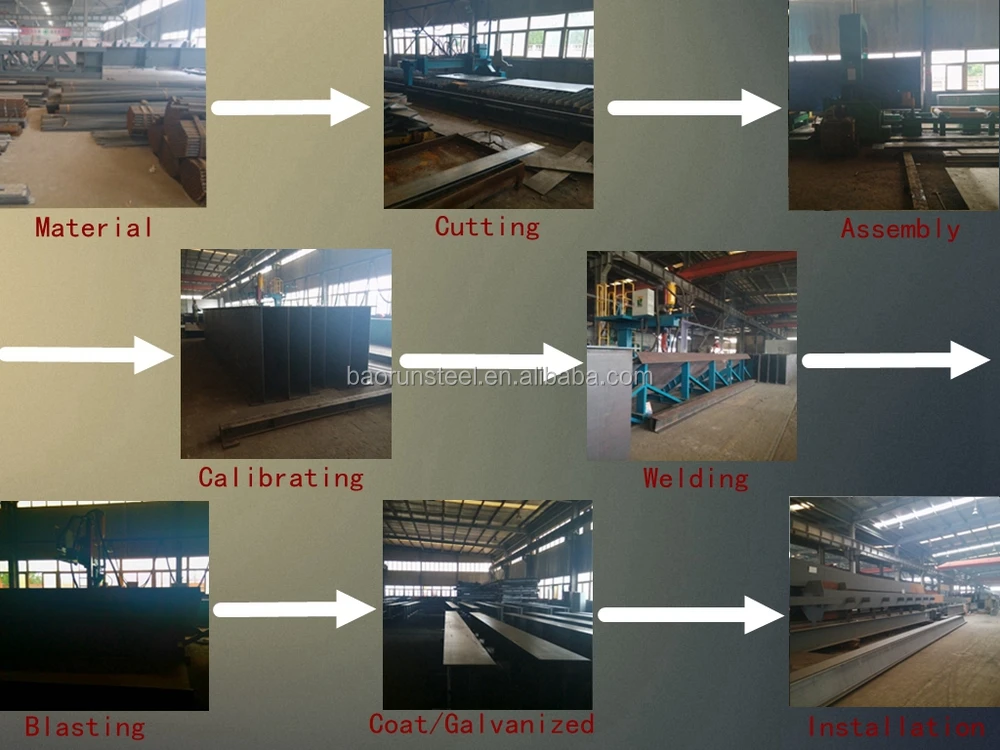

production process

We have 2 heavy steel production lines and 3 light steel production line ,

Steel structure production process :

Cutting→Assembly → Calibrating→Welding →Blasting→ Coat/Galvanized → Installation

Q1: Would you send engineers to the site to guide for working when installed?

Re:Yes, Usually we will send two engineers to the site.

Q2: Can you design?

Re: We have excellent design team, Our mainly design software are Auto CAD,PKPM,MTS,3D3S, Tarch, Tekla Structures(Xsteel)V12.0.etc

Q3: Are you a factory, Can we visit your factory?

Re:Yes, We are a professional manufacture of steel structure factory. Welcome you to visit our company.

Q4.How can i get the quotation of the project ?

Re: If you have drawing , we can offer you our quotation according to your drawing .

If you have no drawing , Our engineer will design some drawings for you to confirm. And then offer you a quotation.

Q5.Do you offer service for installation?

Re: We will give detailed installation drawings and direction info for free. And we could send engineers as installation director even a team.

Q6.Do you accept container loading inspection?

Re: You are welcomed to inspect our work, not only for the container loading, but any time during the production time.

Steel beam, steel column, crane beams, purlins, support, wall beam, they are prepared in a factory ,

They are installed only need to connect with bolt , This installation is quick and convenient ,

Only need to provide the installation drawings.

contact

Please feel free to contact with me if you are interested.