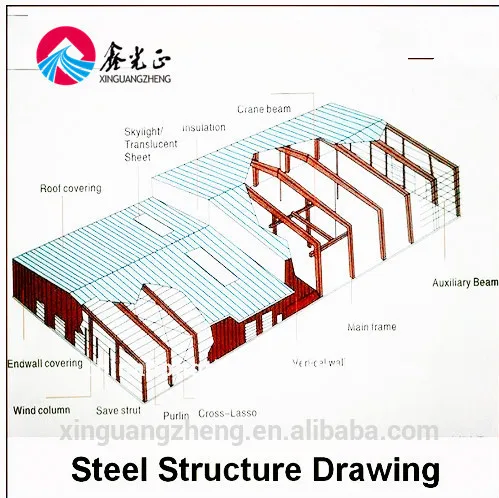

Steel structure drawings : we have a professional technical team yhat can provide you design,structure drawings, 3D pictures, production drawings, installation instructions, etc.

What we do are Turn Key Projects

We can provide you:

| Specifications | 1) Different sizes: |

2) Different types:

double slope Sing span double-span Multi-span single floor, double floors | |

| 3) Different Bases: Cement and steel foundation bolts | |

| 4) Different Columns and Beams: Material Q345(S355JR)or Q235(S235JR) steel, all bolt connections, Straight cross-section or Variable cross-section | |

| 5) Different bracings: X-type or V-type or other type bracing made from angle, round pipe, etc | |

| 6) Different Purlins: C or z type: Size from C120~C320, Z100~Z200 | |

| 7) Different Roof and Wall Panel: Single colorful corrugated steel sheet 0.326~0.8mm thick, (1150mm wide), or sandwich panel with EPS, ROCK WOOL, PU etc insulation thickness around 50mm~100mm | |

| 8) All accessories: Semi-transparent skylight belts, Ventilators, down pipe, Galvanized gutter, etc | |

| 9) Surface: Two lays of Anti-Rust Paint | |

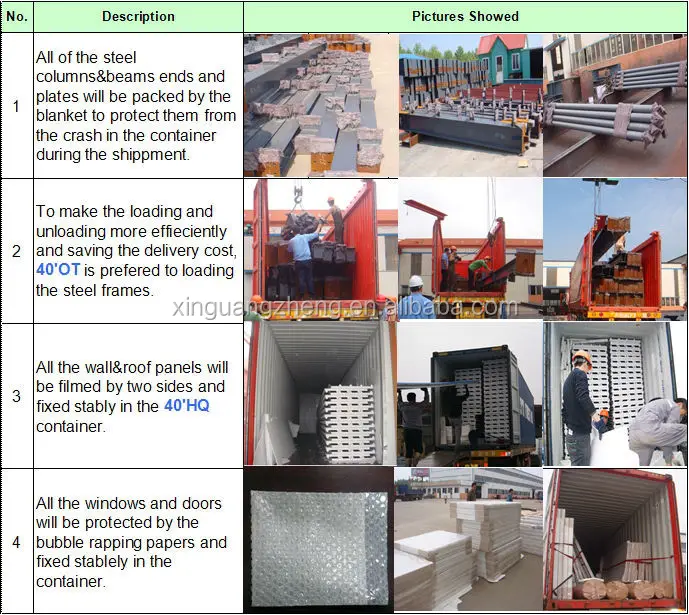

| 10) Packing: Main steel frame without packing load in 40'OT, roof and wall panel load in 40'HQ |

You ONLY need you to provide us with the following information:

Design Parameters | 1) Live load on roof (KN/M2) |

2) Wind speed (KM/H) | |

3) Snow load (KG/M2) - If Applicable | |

4) Earthquake load - If Applicable | |

5) Style of Doors and Windows | |

6) Crane (if you have), Crane span, Crane lift height, max lift capacity, max wheel pressure and min wheel pressure | |

7) Size: width X length X eave height, roof slope | |

8) Or your idea! |

BUT maybe you are unsure about what type or what needs you have regarding you’re warehouse/workshop, or this project is your first one. Don't worry, we will teach you to choose the right style and the finest design within your budget.

Generally speaking,our Steel structure warehouse/workshop are categorized as below:

(1) Simple Steel Structure Warehouse | ||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet | |

| Door | Simple steel rolling shutter (within 10m2) | |

| Window | Very few | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Africa, Middle-East, South America (no snow, wind load below 0.4kn/m2) | |

(4) Cold Region (heavy snow) Steel Structure Warehouse | ||

| Main structure | Single span: L -shorter than 18m, H -lower than 6m | |

| Maintenance system | Roof | EPS/rock wool/PU sandwich board |

| Wall | EPS/rock wool/PU sandwich board | |

| Door | PU foamed rolling door | |

| Window | Alu. Alloy, Hollow glass | |

| Usage | Warehouse, workshop, shopping mall, exhibition hall, super market | |

| Standard and suitable market | Cold regions such as Norway, Russian, North Canada, Finland, Iceland, Greenland, Sweden, etc. (snow loads below 3kn, wind load below 1KN/M2) | |

(5) Steel Structure Warehouse with Crane (5T, 10T, 20T) | ||

| Main structure | Single span: L -shorter than 20m, H -lower than 10m | |

| Maintenance system | Roof | Colored steel sheet with 50mm glass wool insulation |

| Wall | Colored steel sheet or sandwich board | |

| Door | Wind resistance rolling door (within 15m2) | |

| Window | Alu. Alloy (can use with skylight) | |

| Usage | Warehouse, workshop | |

| Standard and suitable market | Snow 0.5kn, wind load below 0.5kn/m2 | |

Color | Decided by customers |

Truss | square tube |

| Roof | Color-steel Sandwich Panel (EPS/rockwool/glass fiber 50mm/75mm/100mm) |

| Wall | Color-steel Sandwich Panel (EPS 50mm/75mm/100mm) PS: customers can choose other sandwich panel material. |

| Door Frame | steel sheets |

| Door | 2000mm*900mm iron security door or PVC door |

Window | PVC Window |

| Earthquake proofing | Grade 7 |

Fire Proofing | Grade 3 |

Wind Proofing | 120km/h |

Good Character:

1.Simple cement foundation

2.Environment protective, no garbage caused

3.Doors, windows, and interior partitions can be flexibly fixed

4.Beautiful appearance, different colors for the wall and roof

5.Cost saving and transportation convenient

6.Can be reused relocated and even resold .

7.Anti-rust and normally more than 15 years using life

steel warehouse

1. easy construction

2. low cost

3. good looking

1. Our prefab steel warehouse is fast and easy erection. Installation with no errors because we adopts pre-installation before we ship the steel structure to ensure the quality of our steel structure products

2. The advanced design can decrease much of the work for civil construction design and shorten the constructing period. Almost no welding at the spot can make the installation much quicker.

3. All the materials of our steel frame are C beam, Z beam, H-shaped steel and the galvanized steel plate or sheet. The grade is upon Euro norm S355JRC or American Norm ASTM A572 grade 50 or equivalent to Q345b.

4. Wall panels and roof panels can be corrugated sandwich board or corrugated steel single panels.

5. Light tile is as per the customers requirement.

6. Use: commonly used in industrial factories, warehouse, commercial buildings, distribution centers, hangars and multi-story steel buildings.

steel construction details:

Our light steel construction can save time and can be installed in any weather. Also the house have advantage of is fire-proof, heat/cold-insulation, non-shrinking and enlarge the work size and have little pollutions, we produce and install different kinds of light steel construction which have a good framework. They are safe, easy to install and disassemble, also can be used multiple times without special tools. Special used in warehouse, workshop, temporary office, etc. We have an excellent designing team and we can produce according to the customers' requirements.

Steel construction Features:

1) Prefabricated and customized design

2) Low foundation cost, thanks to the light weight of the structure itself

3) Easy construction, time-saving, and Labor saving

4) Flexible layout, beautiful appearances, and higher space efficiency

Steel Construction Technical Parameters :

Item Name | steel construction |

Main Material | Q235/Q345 Welded H Beam and Hot Rolled Section Steel |

Surface | Painted or Hot Dip Galvanized |

Roof & Wall Panel | EPS Sandwich panel /Single Corrugated Steel Sheet/ Colour sheet with Glass-wool, for customers choose |

Window | PVC Steel or Aluminum Alloy |

Door | Sliding Door or Rolling Up Door |

Service | Design, Fabrication and Installation |

We can make quotation according to customer's drawing or requirement | |

(size by length/width/height and wind speed), offering a free design | |

drawing and all detailed drawings for installation. | |

Packing | According to customer's requirement |

Load into 40/20GP,40HQ or 40OT |

Product Description:

The load bearing parts for steel structure workshop are mainly

steel structures, including steel columns, steel beams,steel structural basements, bracing systems for wall and roof.

Steel workshops are divided into Light Steel Workshops and Heavy Steel

The Main Structure are usually made of Q345 Steel while the Purlins and Bracing System are made of Q235 Steel.

They are the most common steel materials used for steel structure

in China.

Advantages of Steel Structural Workshop:

1).Large span for great strength with light deadweight;

2).Short finishing time and low cost;

3).Fire proof and rust proof;

4).Convenient to assemble or disassemble.

Technical Parameters:

1.Main Structure: Steel Welded H Section

2.Purlin: C Section Channel or Z Section Channel

3.Roof Cladding: Sandwich Panel or Corrugated Steel Sheet with Fiber

Glass Wool Coil

4.Wall Cladding: Sandwich Panel or Corrugated Steel Sheet

5.Tie Rod: Circular Steel Tube

6.Brace: Round Bar

7.Column & Transverse Brace: Angle Steel or H Section Steel or Steel

Pipe

8.Knee Brace: Angle Steel

9.Wrapping Cover:Color Steel Sheet

10.Roof Gutter: Color Steel Sheet

11.Rainspout: PVC Pipe

12.Sliding Sandwich Panel Door or Metal Door

13.Windows: PVC/Plastic Steel/Aluminum Alloy Window

14.Connecting: High Strength Bolts

1. Wall and roof materials : EPS/Rockwool/PU/PIR Sandwich Panel

2. Color: normally, white gray, blue and red;

3. Moudle: Single slope or double slop;

4. Window material: Plastic steel or aluminum, swing or slidding

5. Door: EPS Sandwich panel, PU sandwich Panel, Plastic steel or Aluminum.

Material Standards:

1. International standard: Fe360B

2. Chinese standard: Q235B/ Q345B

3. European standard: A37-2

4. Japanese standard: SAPH38(G3133-87)

5. American standard: A283GRC

Function:

Beam, column used as various steel structure beam and column on workshop, warehouse, office building and power plant

Coating:

1. Painting:Alcohol acid paint, epoxy zinc rich paint and chlorinated rubber paint. Various colors

available.

2. Hot dip galvanizing: The hot dip galvanizing thickness is about 60~120 microns and

275~500g/square meters

Steel structure Factory Features:

1. Reliable structure:

light steel structure is the frame of our building, which meets the design requirements of steel structure.

2. Easy to install and disassemble:

Standardized components make it easy to install and dismantle. It is especially suitable for emergency projects.

3. Attractive appearance:

Because prepainted steel sheet or sandwich panel is adopted, the whole structure is handsome.

4. Environment friendly and economical:

Reasonalbe design makes it reusable. The reusable character makes it environment friendly and economical.

5. Cost efficient:

First class material, reasonable price, once and for all investment, low requirements for base and short completion time make it cost efficient.

6. Relocatable:

It can be relocated up to 10 times. It has 15 to 20 years durability