The fastest delivery time brushed surface pe coated aluminum composite panel factory alu compound sheet

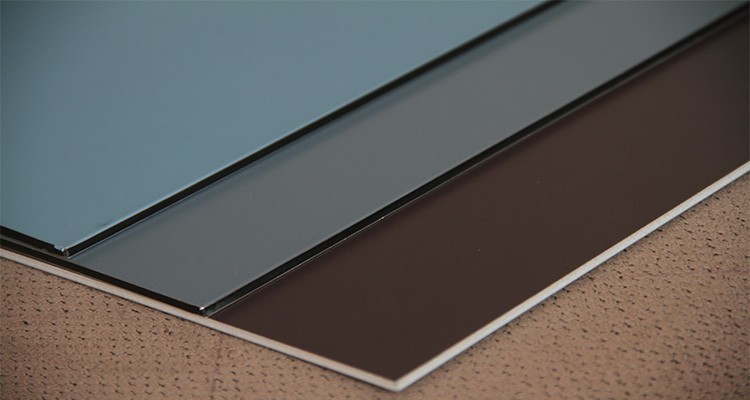

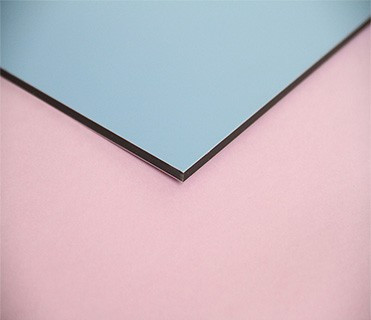

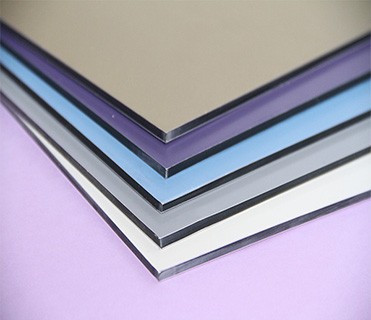

PVDF Aluminum composite panel consists of two layers of aluminum skin sandwiching a PE core in a continuous extrusion process. The outer surface of panel is coated with PVDF Kynar500 fluorocarbon coating to provide a long lasting, durable finish for wall cladding applications

Raw Material

Base material: High strength aluminum alloy sheet

PE core material: Non-toxic low density polyethylene

Surface coating: PVDF Lynar500 coating

Back coating: Primer coating

Technical Data

Paint thickness: 25-28 micron

Paint type: Kynar 500 PVDF coating

Warranty: 15-20 years

Fire resistance: B-s1-d0 according to EN13501

Application:

Office buildings, Shopping centers, Industrial buildings, Airports, Hotels, Bus center, Hospital, Schools, Supermarket, Residential buildings.

APPLICATIONS:

Wallboards and ceiling for tunnels

Materials for industrial application ,car and ship bodies.

Curtain wallboards for outside walls of normal buildings

In interior wall ,ceiling, kitchen ,and interior decoration.

Facades and balconies ,shopping malls ,airport, stadium, plaza and so on.

Our Main Product

the company main products are aluminum veneer, aluminous model board, glass magnesium board, foam layer of new type building decoration materials such as aluminum coil and white carbon black, building decoration materials is according to the requirements of customers design, produce products that meet the customer requirement.

Company Technology

the company technology center is equipped with process development room, mould development room, four technical department, quality control, product laboratory is mainly responsible for the research and development of aluminum-plastic board, aluminum veneer and white carbon black inspection work, the company has five production workshop, the aluminum sheet.

The fastest delivery time brushed surface pe coated aluminum composite panel factory alu compound sheet

The fastest delivery time brushed surface pe coated aluminum composite panel factory alu compound sheet